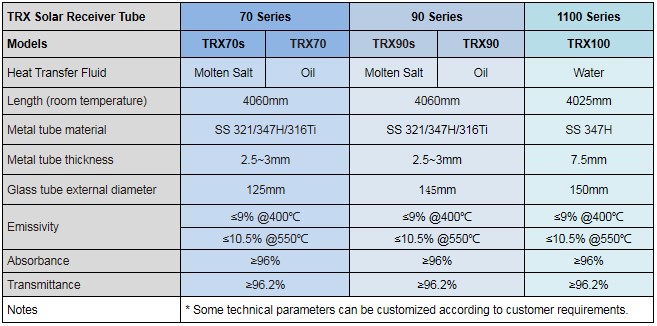

At present, there are three series (70, 90 and 100), and five models of receiver tubes.

Suitable for trough solar station, linear Fresnel power station and integrated solar energy station.

Cover different types of heat transfer fluid: oil, molten salts, water, etc.

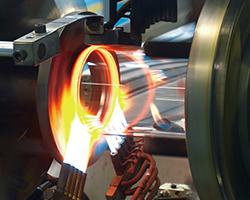

Passed the test of international authority, and achieved the world's leading heat loss and optical efficiency result.

High quality standards ensure the highest optical and thermal performances, and allowing the maximum efficiency of the operating plant.

Technical Advantages

+

Technical Parameters

+